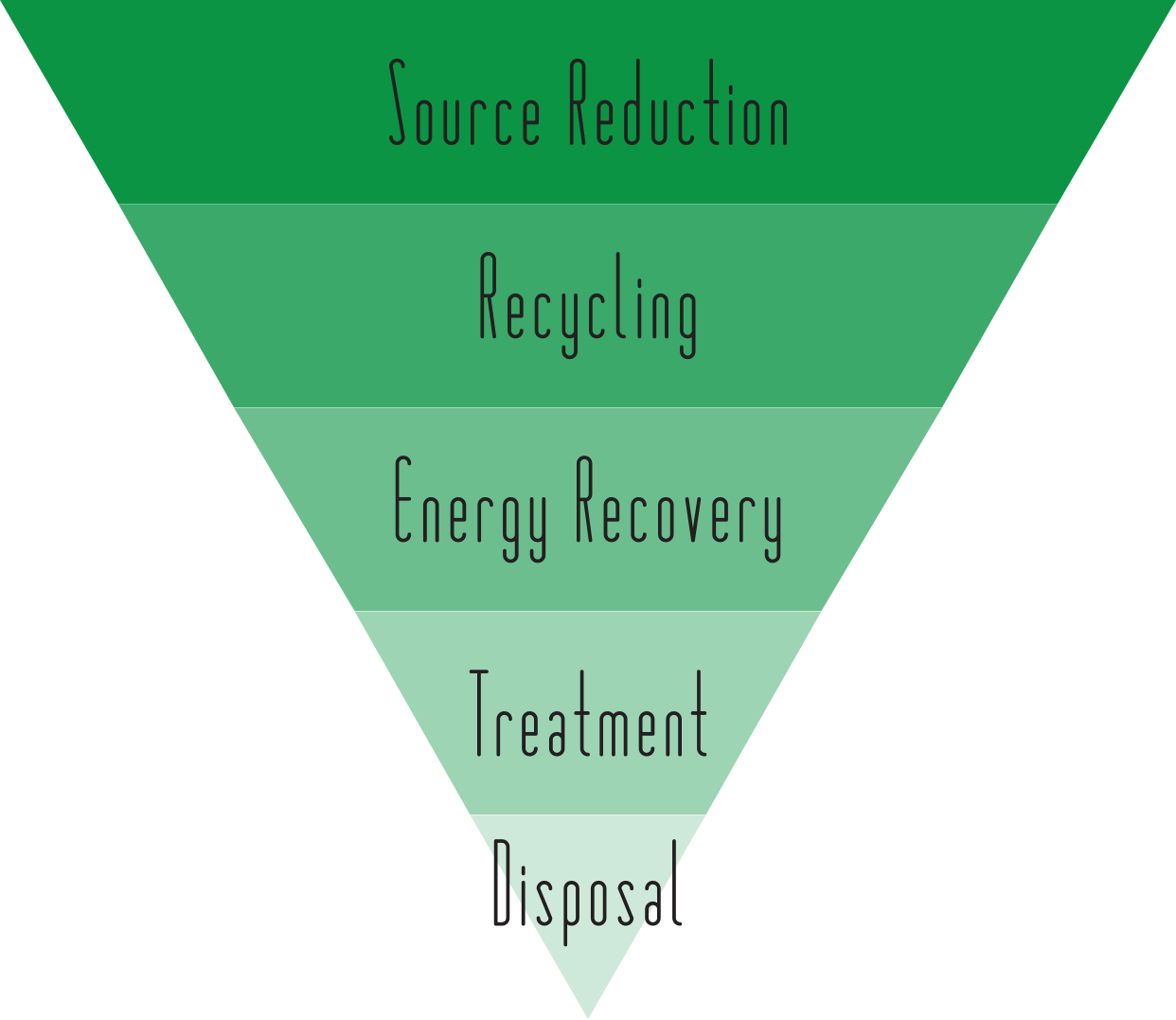

A couple of weeks ago we did a post on how the government is addressing waste minimization. Here we’ll talk more about what waste minimization is. According to the EPA, “Waste Minimization refers to the use of source reduction and/or environmentally sound recycling methods prior to energy recovery, treatment, or disposal of wastes.” Ergo, treatment of a wastestream does not constitute waste minimization. The EPA takes this further by clarifying that “compacting, neutralizing, diluting, and incineration are not typically considered waste minimization practices.” So in the hierarchy of materials management source reduction and recycling come before energy recovery, treatment, or disposal.

What is Source Reduction?

Source reduction (which is also known as pollution prevention or P2) is a practice that reduces or eliminates the creation of wastes at the source. Additionally, source reduction “refers to any practice that reduces the use of hazardous materials in production processes.” The EPA lists the following examples of source reduction:

- “Early retirement of equipment such as mercury-containing devices like switches and thermostats;

- Reformulating or redesigning products, such as creating new PVC compounds without using lead;

- Using less toxic feedstocks, such as switching to the use of lead-free solder in manufacturing;

- Improving work practices, such as reorganizing paint batches in order to reduce cleaning operations.”

How is Recycling Utilized?

While most of us know about recycling from a personal standpoint we probably still can learn about recycling at the manufacturing level. In most cases recycling is used when source reduction is not seen as practical economically. In the manufacturing process, “Recycling includes the reuse or recovery of in-process materials or materials generated as by-products that can be processed further on-site or sent offsite to reclaim value. Recycling is a broad term that encompasses the reuse of materials in original or changed forms rather than discarding them as wastes. Recycling can also be thought of as the collection and reprocessing of a resource so it can be used again, though not necessarily for its original purpose.” The EPA provides a few examples of the types of recycling that can be used for waste minimization:

- “Direct use/reuse of a waste in a process to make a product, such as reusing a purge product used to clean paint lines rather than disposing of it by incineration.

- Processing the waste to recover or regenerate a usable product, such as collecting vapor from dry cleaning operations, turning it back into liquid, and reusing the liquid to clean more clothes.

- Using/reusing waste as a substitute for a commercial product. When mercury is recycled from old equipment like switches, it can be used in new products that still require mercury, such as fluorescent bulbs. Recycling of mercury has been so successful that there is now enough recycled mercury in the U.S. that manufacturers do not need to use new mercury from mines.”

How can Waste Minimization help companies?

Aside from being good for the environment, waste minimization can help companies on an economic sense by eliminating wasted materials, improving production efficiency, and improving product quality. Additionally, the EPA states that “reducing waste generation through waste minimization has helped some companies change their RCRA regulatory status from large quantity generator (1000 or more kilograms of hazardous waste generated per month) to small quantity generator (between 100 and 1000 kg of hazardous waste generated per month), or to conditionally exempt small quantity generator (up to 100 kg of hazardous waste generated per month). Some have managed to eliminate the generation of hazardous waste and avoid RCRA regulatory requirements altogether.”

What do you think about waste minimization? Does your company have plans and processes in place to achieve waste minimization goals? Have you seen a good ROI on your efforts? We’d love to hear about it in the comments section!

Quoted and cited information (unless otherwise noted) for this blog post was gathered from the EPA FAQ Page on Waste Minimization. As always, this blog post is not intended to be comprehensive and it is always best to check with the EPA and local government for full, up-to-date, rules and regulations.

More News From Heritage

-

Published Articles 8/2/22

How Safety, Maintenance, and Reliability Are Intertwined

VP of Health and Safety Jim Mangas discusses the importance of plant safety, maintenance, and reliability (featured in BIC Magazine July/Aug '22)

-

Blogs 7/28/22

Spotlighting Our Environmental Interns

Highlighting some of the wonderful interns we have at Heritage this year!

-

Blogs 7/11/22

Turning Hazardous Waste into an Alternative Fuel

In this blog we walk you through the process of fuel blending, where we can turn hazardous waste materials into a viable alternative fuel source.

-

Community News 6/15/22

2022 Habitat for Humanity Build

Our 12th annual Habitat for Humanity Build

-

Blogs 4/13/22

After Hurricane Ida, Our Port Fourchon Office Rebuilds

On August 28th, 2021, the Louisiana coast was battered by Hurricane Ida. This included our Port Fourchon Service Center, where the devastating hurrica

-

Community News 4/7/22

Heritage readies for Earth Day HHW collection in East Liverpool

Heritage Thermal Services is pleased to announce that its collection of household hazardous wastes for the East Liverpool area returns for 2022.

-

Published Articles 4/2/22

The Impact of Changing Conditions

VP of Health and Safety Jim Mangas discusses preparedness for unexpected conditions during a project. (featured in BIC Magazine March/April '22)

-

Blogs 3/11/22

International Women’s Week Spotlight – Rachel McGrogan

Rachel McGrogan speaks about her time as a Lab Chemist at Heritage.