The Challenge

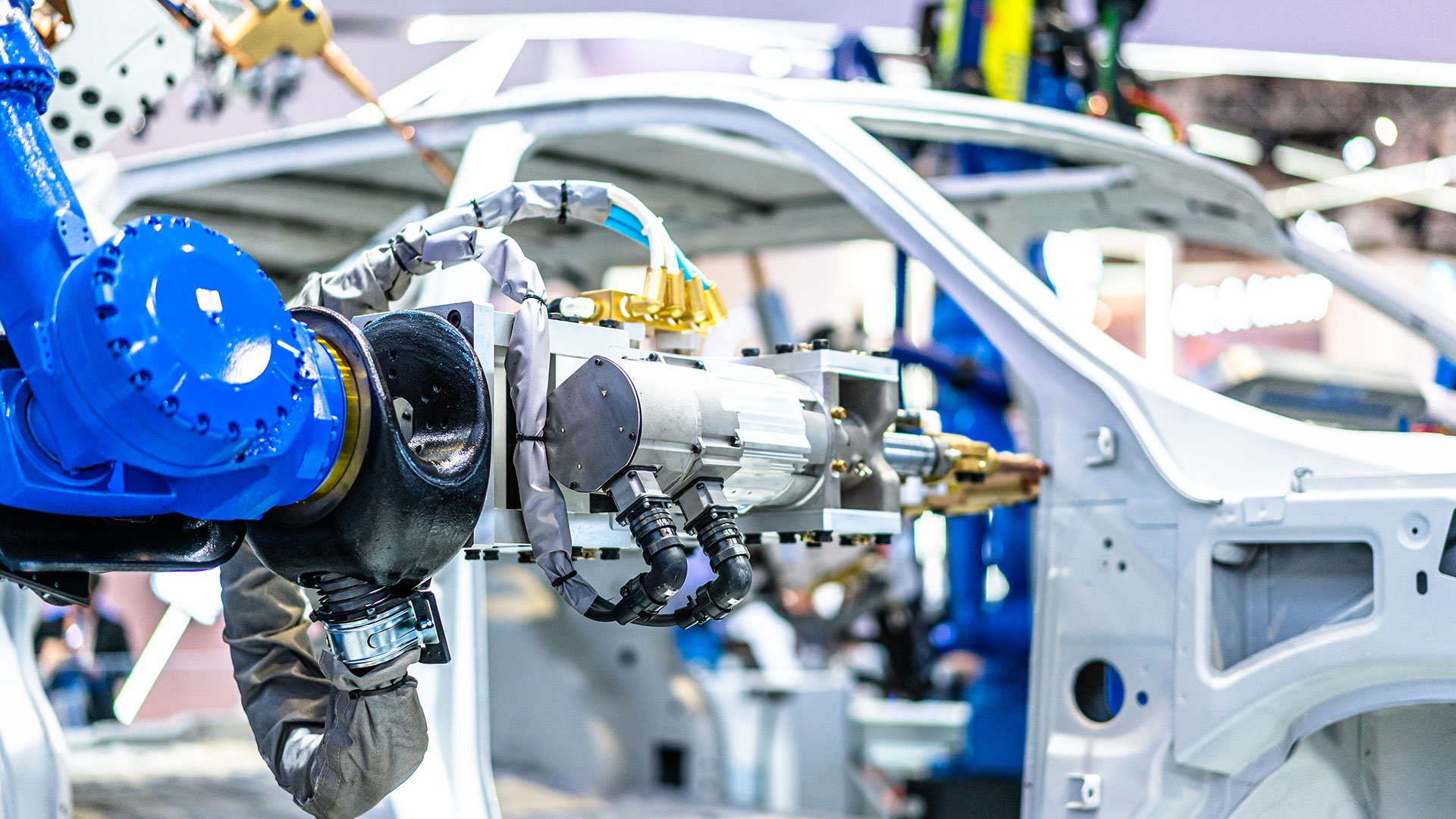

This global auto manufacturer wanted to reduce global waste to landfill by 40% per vehicle from 2011-2016. To do this they wanted to increase the number of zero-waste-to-landfill plants. They do not have a zero-waste-to-landfill plant in Mexico. The goal is to be the first Zero Waste to Landfill (ZWTL) plant in Mexico.

Better VISIBILITY

Initially, Heritage created a baseline for the manufacturing facility and determined that 14 roll-off shipments of waste were sent to landfill each month.

Next steps included exhaustive audits to determine optimum segregation of materials for landfill diversion. And only then a campaign to educate personnel to properly use the segregation containers was established and implemented.

Better SOLUTIONS

The Heritage team worked with the Ford site personnel to implement the segregation process at the generation point. Additional labor force was then assigned to the segregation process to ensure accuracy.

To help off-set the additional labor cost, Heritage installed a baler to maximize trash compaction. Next, with the cooperation of a Heritage cement kiln partner, multiple trials runs were completed until an optimum fuel sample was achieved.

Proven IMPACT

Better segregation of the waste greatly increased the volume of waste that could be recycled instead of landfilled. And, the baling of trash maximized loads to reduce transportation costs. These changes resulted in reducing loads from 14 to 2 per month.

Zero Waste to Landfill status was successfully achieved at this Ford facility in only 18 months.

-

1st ZWTL facility in Mexico

-

26 Plants have achieved zero-waste-to-landfill

-

227.4 Tons of landfill waste are diverted annually